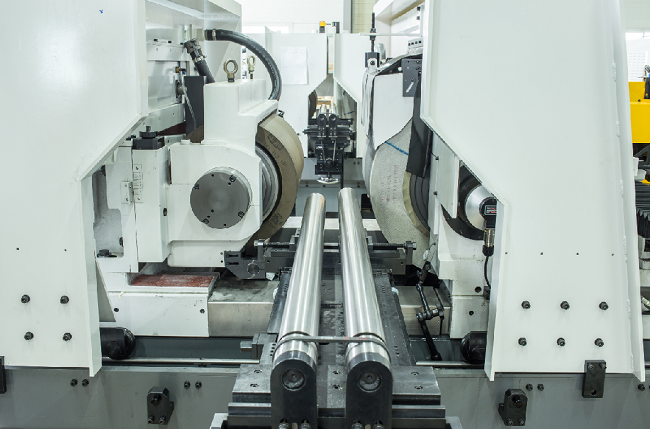

Thrufeed Centerless

- The process that is followed by our team at Mid Valley to produce the best thrufeed centreless is as followed:

- The workpiece as a shaft is taken care of through a help edge focused between two rolls. The distance between the rollers is somewhat more modest than the breadth of the workpiece.

- One roll is the crushing apparatus and the second roller directs the turn of the workpiece.

- The rollers are somewhat shifted permitting the workpiece to be gradually moved pivotally along the help edge so that no taking care of instrument or installation is required.

- The process is typically upheld by a cutting liquid for cooling and expulsion of the chips. High virtue is essential to not influence the crushing outcome.

- We’re ready to robotize our thrufeed centreless tasks using vibratory dishes, which take into account persistent taking care of. This is ideal for our clients that have a high volume of results, and we can give serious valuing choices.